- Network Sites:

-

EEPower Day is a free 1-day virtual conference. Learn More

EEPower Day is a free 1-day virtual conference. Learn More

A wirewound resistor is an electrical passive component that limits current. The resistive element is an insulated metallic wire that is wound around a core of non-conductive material. The wire material has a high resistivity, and is usually made of an alloy such as nickel-chromium (Nichrome) or a copper-nickel-manganese alloy called Manganin. Common core materials include ceramic, plastic, and glass. Wirewound resistors are the oldest type of resistors that are still manufactured today. They can be produced very accurately and have excellent properties for low resistance values and high power ratings.

A wirewound resistor is an electrical passive component that limits current. The resistive element is an insulated metallic wire that is wound around a core of non-conductive material. The wire material has a high resistivity, and is usually made of an alloy such as nickel-chromium (Nichrome) or a copper-nickel-manganese alloy called Manganin. Common core materials include ceramic, plastic, and glass. Wirewound resistors are the oldest type of resistors that are still manufactured today. They can be produced very accurately and have excellent properties for low resistance values and high power ratings.

A wirewound resistor is a resistor where a wire with a high resistivity is wrapped around an insulating core to provide the resistance.

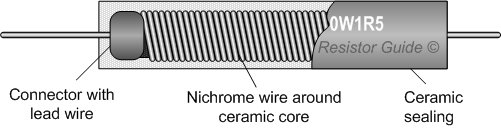

Example of a wirewound resistor construction

Example of a wirewound resistor constructionWirewound resistor construction varies widely. The manufacturing method and choice of materials is dependent on the way the resistor will be used in a circuit. All are made by winding a wire around a core. The resistance value is dependent on the resistivity of the wire, the cross section, and the length. Since these parameters can be accurately controlled, a high precision resistance can be achieved. For high tolerance requirements, the resistance value is measured to determine exactly the length to cut the wire. To create a high resistance, the wire diameter needs to be very small and the length very long. Therefore, wirewound resistors are mainly produced for lower resistance values. For low power ratings, very thin wire is used. The handling of very thin wire is critical. Any damage may sever the wire. After winding, the wire is well protected from moisture to prevent electrolytic corrosion.

There are also wirewound resistors with a high power rating for 50 W or more. These resistors have a quite different construction. Compared to other resistor types such as metal film, the wire diameter is relatively large and, therefore, is more robust.

Wirewound resistors are mainly produced with alloys, since pure metals have a high temperature coefficient of resistance (TCR). However, for high temperatures, pure metals such as tungsten are often used. The temperature coefficient is a measure of how much the resistance will change as the temperature changes. TCR is measured in units of ppm/˚C. If a manufacturer rates a resistor at 50 ppm/˚C, the resistor will not change more than 50 Ω in resistance for each 1 MΩ of the resistors given value, for a temperature change of 1 ˚C. Typical alloys that are used as resistor wire are:

In the following table the properties of the most common alloys are given.

| Alloy Group | Material | Composition (%) | Resistivity (10-6 Ω/m) | TCR (10-3 Ω/˚C) | Max Temp(˚C) |

|---|---|---|---|---|---|

| Copper | Constantan | 54Cu - 45Ni - 1Mn | 0.485 | 0.2 | 400 |

| Nickelin | 67Cu - 30Ni - 3Mn | 0.40 | 0.11 | 300 | |

| Manganin | 86Cu - 2Ni - 12Mn | 0.442 | 0.02 | 300 | |

| Silver | N.B.W. 109 | 82Ag - 10Mn - 8Sn | 0.55 | 0.0 - 0.04 | |

| N.B.W. 139 | 78Ag - 13Mn - 9Sn | 0.61 | 0.0 - 0.08 | 0 - 150 | |

| N.B.W. 173 | 80Ag - 17Mn - 3Sn | 0.58 | 0.0 - 0.105 | 0 - 200 | |

| Nickel Chromium | Nichrome | 77/80Ni - 20Cr - 0/2Mn | 1.105 | 0.17 | 1100/1150 |

| Iron Chromium | CrNiFe 1 | 70Ni - 20Cr - 8Fe - 2Mn | 1.11 | 0.9 | 1050/1100 |

| CrNiFe 2 | 63Ni - 15Cr - 20Fe - 2Mn | 1.12 | 0.89 | 1050/1100 | |

| Iron Chromium Aluminum | Kanthal A | 72Fe - 20Cr - 5Al - 3Co | 1.45 | 0.06 | 1300 |

| Cekas | 75Fe - 20Cr - 5Al | 1.4 | 0.04 | 1300 | |

| Megapyr | 65Fe - 30Cr - 5 Al | 1.4 | 0.025 | 1350 | |

| Pure Metals | Tungsten | 100W (sintered) | 0.0553 | 4.5 | 1500/1700 |

For high precision measurement applications, the difference in material of the resistor wire and the connecting leads can cause a negative effect. At the junction between the materials a change in temperature can cause a small unwanted voltage across the resistor. This is called the thermoelectric effect.

Wirewound resistors naturally have some parasitic capacitance and inductance. Because of this, they influence the current flow in an alternating current circuit. These effect of these parasitics is usually undesirable. DC currents are less effected by the parasitic capacitance and self induction than AC currents.

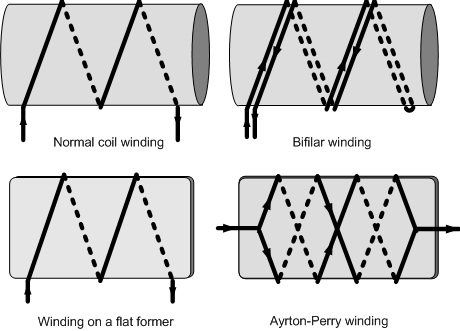

Because of the design principle of the wirewound resistor, which is basically an inductor, these resistors have the worst high frequency properties of all resistor types. There are several ways to apply the winding, depending on the application of the resistor. To reduce these parasitic effects, several specialized winding types exist:

Wire winding techniques to reduce parasitics

Wire winding techniques to reduce parasitics

These types of windings are applied for measurement devices and decade banks. The drawback of these methods is the difficulty of the manufacturing process.

Wirewound resistors can roughly be classified in two types: precision and power. They can be modified for use in current sensors, temperature sensors, and potentiometers. These versatile resistors can be used in a wide range of applications.

High precision wirewound resistors are typically used in precision audio frequency (AF) attenuators, measurement bridges, and calibration equipment. Typical values for the tolerance of the resistance value is 0.1% or better. The temperature coefficient of resistance is typically about 5 ppm/°C, which is considerably better than most metal film resistors (around 25 ppm/°C). The stability is also fairly good, with values of 35 ppm change for a year of operation at full power rating. The temperature rise of these resistors is usually below 30 °C. Therefore they can be coated by epoxy resin materials. In practice, a designer might decide that a resistor needs to be within ±0.05% of the design value for a particular circuit application. To account for aging, TCR and other parameters, the designer might then specify a tolerance of ±0.01%. This ensures that the resistor stays within the required resistance range over time and varying circuit conditions.

High precision wirewound resistors are typically used in precision audio frequency (AF) attenuators, measurement bridges, and calibration equipment. Typical values for the tolerance of the resistance value is 0.1% or better. The temperature coefficient of resistance is typically about 5 ppm/°C, which is considerably better than most metal film resistors (around 25 ppm/°C). The stability is also fairly good, with values of 35 ppm change for a year of operation at full power rating. The temperature rise of these resistors is usually below 30 °C. Therefore they can be coated by epoxy resin materials. In practice, a designer might decide that a resistor needs to be within ±0.05% of the design value for a particular circuit application. To account for aging, TCR and other parameters, the designer might then specify a tolerance of ±0.01%. This ensures that the resistor stays within the required resistance range over time and varying circuit conditions.

Wirewound resistors exist for very high power applications. The range varies from 0.5 W to more than 1000 W. Power wirewound resistors can be divided into types according to the coating type.

Wirewound resistors exist for very high power applications. The range varies from 0.5 W to more than 1000 W. Power wirewound resistors can be divided into types according to the coating type.

Silicone resins are used for the lowest power dissipation levels. These are compact resistors that can withstand increases in temperature up to 300 °C above the ambient temperature.

Another type of coating is vitreous enamel. This traditional coating has good insulating properties at low temperatures, but the insulating capability is reduced when operated at the full rated temperature. This property makes it less commonly used. The maximum working surface temperature is up to 400 °C. The TCR varies from 75 to 200 ppm/°C, and typical resistance values are in the range from 1 Ω to 10 kΩ.

The majority of the power wirewound resistors have a ceramic core and a ceramic coating to protect the winding. The ceramic coating combines a high insulation and physical protection with good heat dissipation. Typical power ratings are between 4 and 17 W. The maximum surface temperature is around 300 °C and the TCR varies from 250 to 400 ppm/°C. The resistance values are between 10 kΩ and 22 kΩ. Usually they are manufactured with leads that allow for vertical or horizontal mounting.

For the highest power dissipation values, wirewound resistors have an aluminum case with fins. These fins give a larger surface area from which to dissipate heat, letting the resistor handle more power without being damaged. These resistors have a ceramic core and a silicone resin coating, encased in an aluminum extrusion. The surface is anodized to maintain a good insulation resistance. These power wirewound resistors have a typical power rating of 25 to 50 W. This assumes that the resistor will be mounted on a metal surface to assist with the power dissipation. The maximum surface temperature is around 300 °C and the TCR is low with around 25 ppm/°C for resistance values above 50 Ω. Usually the TCR is higher for lower resistance values.

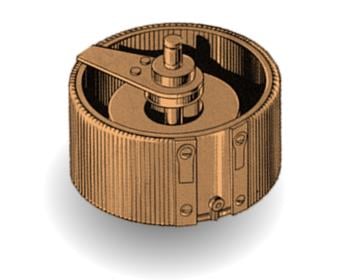

Potentiometer wirewound

Potentiometer wirewoundPotentiometers are often wirewound resistors. A potentiometer is a resistor that has three terminals. One of these is attached to a movable contact that varies the amount of resistance. Wirewound resistors are suitable as potentiometers because of their durable construction.

Wirewound resistors are often used in circuit breakers or as fuses. To make a fusible resistor, the manufacturer attaches a small spring to one end of the resistor. A small amount of solder will hold this spring in place. If current and heat through the resistor gets high enough, the solder will melt and the spring will pop up and open the circuit. Because of their high power capabilities, wirewound resistors are common in circuit breaker applications. The may be used as components in a large circuit breaker device, or may act as circuit breakers themselves.

When fusible wirewound resistors are sold for use in high power applications, they are often labeled as circuit breakers. Wirewound resistor potentiometers can be made to offer both high power and high precision. These potentiometers are often used in stereo systems for their precision and in high power applications like transducers and televisions. Wirewound resistors can also be used as temperature sensors. In this case, metal that has a positive temperature coefficient is used. This means that as the temperature of the metal rises, the resistance rises. This varying resistance can be measured and converted back to a temperature value.

Enhancing the inductive effect that is natural to wirewound resistors can let these resistors be used as current sensors. Inductive reactance is determined by the inductance of the device and the current flowing through it. Current sensing devices measure the reactance and convert it to a current reading. These are used in situations where a high current condition may occur, and it is desirable to correct it before tripping a breaker. Large cooling water pumps and freezer units are examples of this type of application.

This is very helpful and informative