- Network Sites:

-

EEPower Day is a free 1-day virtual conference. Learn More

EEPower Day is a free 1-day virtual conference. Learn More

Noise is an unwanted phenomenon for resistors. For some applications the noise properties are important. Examples are high gain amplifiers, charge amplifiers, and low-level signals. Resistor noise is often specified as microvolts noise per volt of applied voltage, for a 1 MHz bandwidth. Thermal noise is the predominant source of noise for resistors. It is dependent on three variables: resistance, temperature and bandwidth. The relation between these three parameters is described by the formula:

$$ E = \sqrt{4 · R · k · T · \Delta F} $$

Where E is the RMS noise signal in volts, R is the resistance in ohms, k is Boltzmann’s constant, T is the temperature in Kelvin and ΔF is the bandwidth in Hz. The equation shows that the noise level can be decreased by reducing the resistance, the temperature or the bandwidth. Knowing Boltzmann’s constant, the formula is simplified to:

$$ E = 7.43\sqrt{R · T · \Delta F} $$

Where E is now the noise voltage in nanovolts, R in kΩ, and ΔF in kHz.

There are two types of noise: the thermal noise and the current noise. To understand these principles, they will be discussed in more detail. In all materials, the electrons constantly move. As temperature increases, the movements increase. The vibrations of the electrons cause a constantly changing electric signal across the terminals of the component. Because the vibrations are completely random, the electrical signal is noise. This is called thermal noise or Johnson noise. It is the main contributor to noise for resistors. Thermal noise is constant over a wide frequency range. Current noise however, declines when frequency is increased. The thermal noise increases with a larger resistance value, while the current noise decreases.

The way to measure resistor current noise is defined in standard IEC 60195. This makes the comparison of different manufacturers possible. The current noise of a resistor is described by the current noise index with a code number.

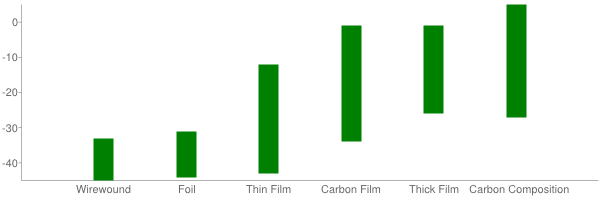

Thin film, metal foil and wire wound resistors have better noise characteristics than other types. Therefore, they are often specified in low-noise amplifying applications. Carbon composition and thick film resistors are some of the worst types. They have high noise due to their construction and materials.

Noise index (dB) for the main resistor types

Noise index (dB) for the main resistor types

In every amplifier circuit, the input resistor is critical. Any noise at the input signal will be amplified by the full gain. It is therefore of high importance to choose a low-noise resistor at the first stage, as well as a low resistance value. This is however not necessary for a load or amplifier feedback resistor, since the gain that is obtained from a high resistance value outweighs the higher noise level. Because thermal noise is temperature dependent, it is very effective to cool the input stages to achieve a low-noise performance.