- Network Sites:

-

EEPower Day is a free 1-day virtual conference. Learn More

EEPower Day is a free 1-day virtual conference. Learn More

Metal film resistors have a thin metal layer as resistive element on a non-conducting body. They are among the most common types of axial resistors. Other film type resistors are carbon film and thick and thin film resistors. In most literature, the term "metal film resistor" implies it is a cylindrical axial resistor. However, thin film chip resistors use the same manufacturing principle for the metal layer. The appearance of metal film resistors is similar to carbon film resistors, but their properties for stability, accuracy, and reliability are considerably better.

Metal film resistors are axial resistors with a thin metal film as the resistive element. The thin film is usually deposited on a ceramic body.

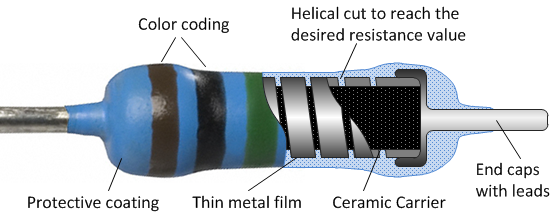

Construction of a metal film resistor

Construction of a metal film resistorThe resistive element is a thin metal layer that is usually sputtered (vacuum deposition) on a cylindrical, high purity, ceramic core. Sometimes, techniques other than sputtering are used. The deposited metal is artificially aged by keeping it for a long period at a low temperature. This results in a better accuracy for the resistor. The resistance material is often nickel chromium (NiCr), but for special applications other alloys are used, such as tin and antimony, gold with platinum, and tantalum nitride.

The stability and resistance are strongly dependent on the thickness of the metal film (50-250 nm). A thicker layer provides better stability and a lower resistance value. On both ends a metal cover is pressed with the connection leads. After this, the desired resistance is achieved by cutting a spiral shaped slot in the thin metal layer. This is usually done by lasers, while in the past sandblasting and grinding techniques were used. Carbon film resistors use the same technique to trim the resistance.

The resistor is covered with several coating layers that are baked individually. The coating protects against moisture and mechanical stresses, and preferably has a high dielectric strength. The resistor value is marked by color code bands or with text. Metal film resistors are available with tolerances of 0.1, 0.25, 0.5, 1 and 2%. The temperature coefficient of resistance (TCR) is usually between 50 and 100 ppm/°C.

Metal film resistors have good characteristics for tolerance, stability, and TCR. Furthermore, the resistors feature low noise properties and a high linearity because of a low voltage coefficient. Therefore, in circuits where tight tolerance, low temperature coefficient, and low noise properties are important, metal film resistors are often used. Examples of applications are active filters or bridge circuits.

For good reliability, metal film resistors are normally operated between 20 and 80% of their specified power rating. Reliability is generally increased by derating 50%. However, in very specific situations including humid environments, the reliability may decrease even when operated at lower than 20% of the power rating. Compared to wirewound or carbon composition resistors, these resistors are more easily damaged by voltage surges and power overloads.

Very will

How to test a resistor and read the findings