- Network Sites:

-

EEPower Day is a free 1-day virtual conference. Learn More

EEPower Day is a free 1-day virtual conference. Learn More

Blower resistors are resistors which are used to control the fan speed of automotive blowers. The fan speed can be changed either by switching the blower resistor resistance mechanically using a rotating lever, or electronically by the air conditioning system. The change in resistance then limits the current through the motor, which dictates the speed at which the blower fan operates. Blower resistors, being a mechanical component, are prone to wear and are the most common point of failure in a car’s heating system. This article will focus on mechanical blower resistors, their construction and troubleshooting.

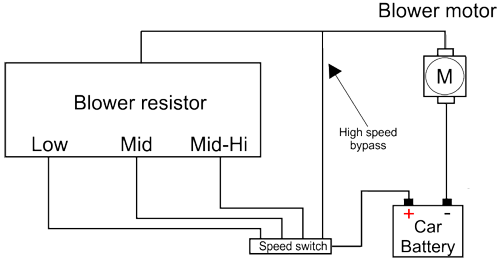

A blower fan is connected to the negative battery terminal (also called ground) on one end and to the positive battery terminal through a blower resistor on the other end. The blower resistor is connected in series with the blower fan. This means that the current running through the blower motor, and thus its speed, is controlled by the resistor value. The user chooses a suitable fan speed by using a selector to connect one of the resistors in the blower resistor pack. Blower resistors are made of several resistors with different resistances. There are also two additional circuits used for the off state and the highest fan speed state. In the off state, the blower motor is disconnected from the power supply. In the highest speed state, the blower resistor is bypassed completely and the fan is connected directly to the car’s battery, which allows maximum current through the motor. The lower the resistance of the selected resistor in a pack, the higher the current that flows through the blower fan, and the faster the fan will turn.

The individual resistors inside the pack are usually wire wound and they may fail by burning out from use, and may also fail due to mechanical stresses and vibrations typically found in an automotive environment. When a blower resistor is faulty, the fan will usually operate at one speed only, usually the highest speed setting possible. Sometimes, only some of the speed settings will be faulty while others might work.

When trying to diagnose a blower fan motor, the following steps should be followed:

If a car’s blower motor doesn’t work at all, there are several components to be checked in the system:

If the fan operates at some speed settings, but doesn’t work at some other speed settings, this means that the blower resistor is faulty and should be replaced:

A word of caution: the blower resistor gets very hot during normal operation, so care must be taken to avoid burns and other injuries.

I congratulate it was a very nice article, but I noticed some deficiencies. You can make up for them.

I am studying and working on it, how do you think? https://aktif.net/en/product-and-services/motor-control-and-braking-resistors/dynamic-braking-resistors

Thanks For Sharing With us.

Visit Here : https://pctlautomation.com/pctl-products/low-voltage-distribution-board/